Respiratory Protection

Oregon-OSHA Requirements

Division 4, Subdivision I: Protective Equipment

Respirators work in two ways: they either purify the existing air with filters, cartridges, or canisters (air-purifying respirators), or they supply clean air through a compressor or a compressed-air cylinder (supplied air respirators).

The most common types of air-purifying respirators used in agriculture are filtering face-piece, elastomeric (able to stretch and return to its original shape), and powered air-purifying respirators (PAPRs).

A PAPR has a battery-powered fan that blows filtered air inside a tight-fitting respirator or loose-fitting hood or helmet (Kasco). Employees with facial hair or facial features that interfere with a tight-fitting respirator can still use a loose-fitting PAPR. Tight-Fitting Facepiece is a respirator covering that forms a complete seal with the face (half mask or full-face piece).

If you require employees to use respirators during work tasks, you must have a Respiratory Protection Program in place. The program must include the following:

- Written Program

- Employee Training

- Medical Evaluations

- Fit Testing

- Recordkeeping

- Cleaning/Maintaining/Repair Respirators

- Evaluate the Respiratory Protection Program Periodically

The program manager must be a “knowledgeable person.” This is someone (you or one of your employees) who has the appropriate training, knowledge, and experience with respirators. The program manager can delegate parts of the program, such as fit testing or respirator cleaning and maintenance, to other qualified employees, but must oversee their activities and the overall effectiveness of the program. No certification is required to manage the Respiratory Protection Program.

When respirators are necessary for workers OR when employers require workers to wear them, you must have a written program with procedures specific to your worksite.

The written program must describe how to do the following:

- Choose the right respirator for the hazardous environment or task.

- Provide medical evaluations for employees who will use respirators.

- Fit test employees who use tight-fitting respirators.

- Train employees to use respirators properly and recognize respiratory hazards.

- Ensure that respirators are properly cleaned, maintained, and stored.

- Establish a schedule for changing filters, cartridges, and canisters.

- Periodically review the program’s effectiveness.

** Sample programs can be found under Additional Resources or on Oregon-OSHA’s website. These sample programs can serve as templates for creating your own written program.

Training must be complete before workers use respirators and must be provided in a language or form that workers understand.

Each employee should know:

- Why respirators are needed at the workplace.

- Why respirators must fit correctly and be properly maintained.

- The capabilities and limitations of different types of respirators.

- When to change filters, cartridges, or canisters.

- How to recognize medical symptoms (such as dizziness or shortness of breath) that limit the safe use of respirators.

- The general requirements of your respiratory protection program.

They must be able to demonstrate these skills:

- How to inspect, clean, and properly store respirators.

- How to seal-check tight-fitting respirators.

- How to identify and choose the correct types of filters, cartridges, or canisters for respirators they will use at the workplace.

- How to change filters, cartridges, or canisters.

- How to properly use any emergency respirators present in their workplace.

Re-train respirator users at least annually. Re-train sooner if:

- Workplace hazards change or employees switch to another type of respirator.

- Employees cannot demonstrate basic understanding or skill with respirators.

Employers must keep the following records for the respiratory protection program:

1. Respirator Protection Written Program

2. Medical Evaluations: All medical evaluations conducted as part of this standard.

3. Fit Testing: Fit testing records for each user that includes:

- Name or identification of employee

- Type of fit test

- Specific make/model/style/size of respirator tested

- Date of test

- Results of fit test (pass/fail results of qualitative fit tests; or the fit factor and strip chart recording for quantitative fit tests)

Fit test records must be kept until records of a new test replace them.

Respirators, training, and medical evaluations must be provided to employees at no cost.

Each employee that is required to use a respirator needs an initial medical evaluation. Those using face piece respirators also require annual fit testing; employees using powered air-purifying helmet respirators (such as Kasco) do not need fit testing.

You must provide medical evaluations to determine each worker’s ability to use a respirator without causing adverse health effects. Do this BEFORE the worker’s fit test and BEFORE they perform any work requiring respirator use.

A medical evaluation can include a medical examination and/or an evaluation of employee responses to the OSHA Respirator Medical Evaluation Questionnaire. Once an employee has an initial medical evaluation, there are no annual or periodic requirements after that. However, certain conditions can trigger medical re-evaluation (see Frequency of Medical Evaluations below for more information). Employers can discontinue an employee’s medical evaluations when the employee no longer uses a respirator.

Medical evaluations must be conducted by a physician or other licensed health care professional qualified to use a medical questionnaire or an exam that obtains the same information as the medical questionnaire.

If the employee refuses the medical exam, they MAY NOT be permitted to work in jobs that require a tight-fitting respirator.

Respirator Medical Evaluation Questionnaire

To start the medical exam process, complete the “employer” section of the medical evaluation questionnaire. Then provide the employee with the Questionnaire (available in English and Spanish) and an envelope. The envelope should be addressed to the medical facility and include pre-paid postage so the employee is not responsible for paying to send the questionnaire.

The employee should complete the “employee” section of the medical evaluation questionnaire, and then use the included envelope to send the document to the medical provider for review.

Once the medical provider has reviewed the questionnaire, they will determine if the employee can be approved for respirator use or if an in-person appointment is needed for further examination.

Protect Employee Confidentiality

The employee must be allowed to complete the questionnaire in a way that protects their confidentiality. Employers are not allowed to see the answers or review the completed form.

Employees must be allowed to complete the form during normal working hours or at a time and place convenient to them. If employees need help, allow them to ask the healthcare provider or anybody other than the employer (or representatives of the employer).

The employee MUST have an opportunity to discuss the questionnaire and exam results with the healthcare provider.

Employer Information Required for Medical Questionnaire

Employers must give the healthcare provider required information before they make any recommendation about a worker’s ability to use a respirator.

Employers are required to provide information in Part B, Section 2 of the Respirator Medical Evaluation Questionnaire to provide the following information:

- The type and weight of the respirator the employee will use.

- How long and how often the employee will use the respirator.

- The expected physical work effort while using the respirator.

- Additional protective clothing and equipment to be worn.

- Temperature and humidity extremes that may exist during use.

This information does NOT need to be provided again for later evaluations of the same employee unless the information or the healthcare provider changes.

Medical Determination

The employer must obtain a written recommendation about the employee’s ability to use the respirator from the healthcare provider.

The recommendation must provide only the following information:

- Any limitations on respirator use relating to the medical condition of the employee or the workplace conditions, including whether or not the employee is medically able to use the respirator.

- The need, if any, for follow-up medical evaluations.

- A statement that the healthcare provider gave a copy of the recommendation to the worker.

If the respirator is a negative pressure respirator and the healthcare provider finds that using it would increase the employee’s health risk, you must provide a PAPR (powered air purifying respirator, such as a Kasco helmet or other type) until a subsequent evaluation clears the employee for another type.

Frequency of Medical Evaluations

Once an employee has an initial medical evaluation before using a respirator, there are no annual or periodic requirements after that.

If the health care professional decides a follow-up medical exam is necessary, the employer must ensure that the follow-up exam is provided. The follow-up exam must include any tests, consultations or diagnostic procedures that the health care provider deems necessary to make a final determination.

A follow-up exam may be required for an employee who responds “yes” to questions 1-15 in Part A of the Respirator Medical Evaluation Questionnaire or whose medical exam demonstrates a need for a follow-up.

Certain conditions can also trigger medical re-evaluation. Additional medical evaluations are also required:

- When the work conditions change (amount of physical work effort, protective clothing, temperatures) that may increase the physical burden to the employee.

- When the respiratory program manager/supervisor/health care professional says another evaluation is necessary.

- When employee(s) show medical symptoms that affect their ability to safely use a respirator.

Changing Healthcare Providers

When the employer replaces a healthcare provider that conducts medical exams for respirator use, they are responsible for making sure that the new healthcare provider has the information from the questionnaire, either by providing the documents directly or by having the documents transferred. However, the employer is NOT expected to have employees medically reevaluated solely because there is a new healthcare provider.

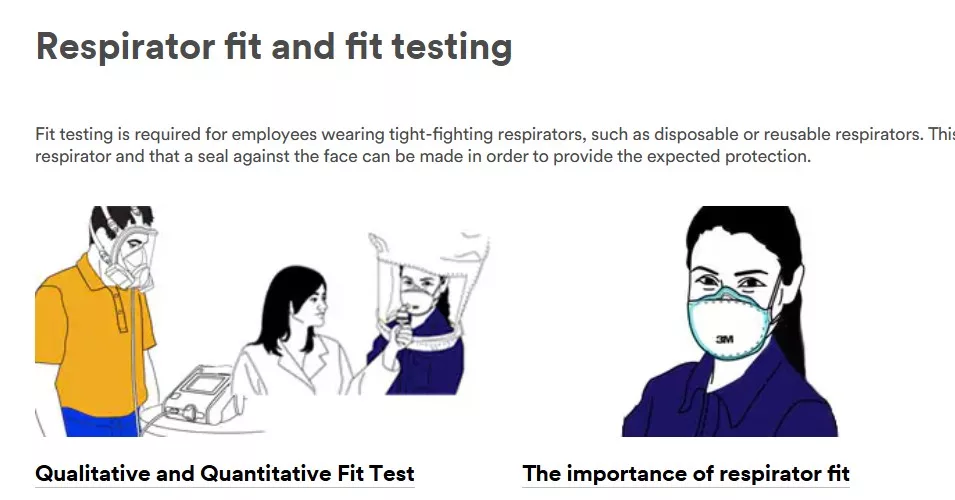

Any employees using a tight-fitting face piece respirator must pass a qualitative fit test (QLFT) OR quantitative fit test (QNFT) using the same make, model, style and size respirator that they will use in the workplace.

QLFT is a pass/fail test that tests the individual’s response to the test agent. QNFT assigns a numerical value to the amount of leakage into the respirator.

The simplest type of fit test is the qualitative fit test. It relies on the respirator user’s response to a test agent such as Bitrex™ or irritant smoke. If the user smells or tastes the test agent while performing the test, the facepiece doesn’t fit or isn’t sealing properly.

Fit Testing Frequency

Fit testing must occur before initial respirator use, and at least annually thereafter.

If the respirator type/style/model/make is changed, a new fit test must be completed before use.

If the worker reports any change in their physical condition that can affect the respirator fit (facial scarring, dental changes, cosmetic surgery, significant change in body weight, etc.), a new fit test should be conducted. If the worker does not report these changes but the employer or supervisor observes them, a new fit test should be conducted.

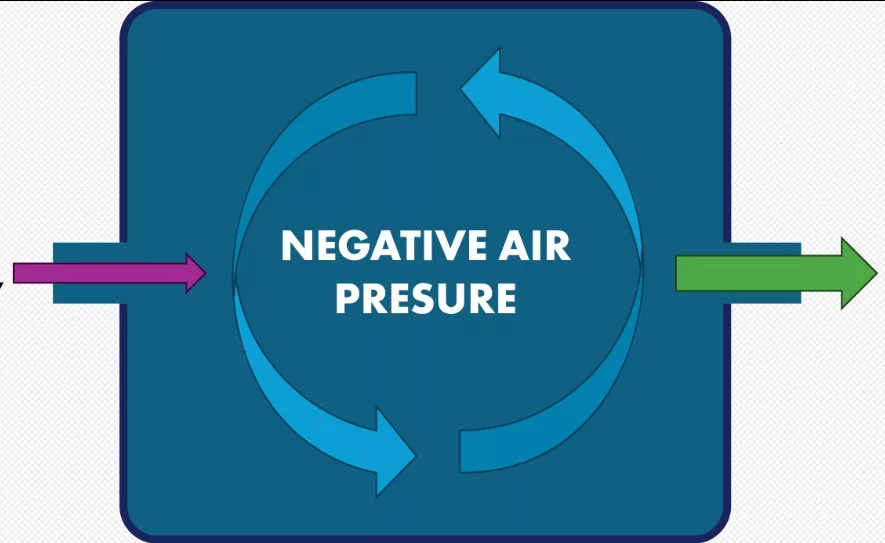

Pressure Mode

Fit testing of tight-fitting atmosphere-supplying respirators and tight-fitting powered air-purifying respirators should only be done when the respirators are in NEGATIVE pressure mode. It does not matter if the mode of operation during use is positive or negative pressure, fit testing should always be done with negative pressure.

Administering Fit Tests

Anyone can conduct a fit test as long as they have the right equipment and follow the protocols in Appendix A of OR-OSHA’s Respiratory Protection Standard. This includes, but is not limited to: employers, outside parties, and respiratory program administrators.

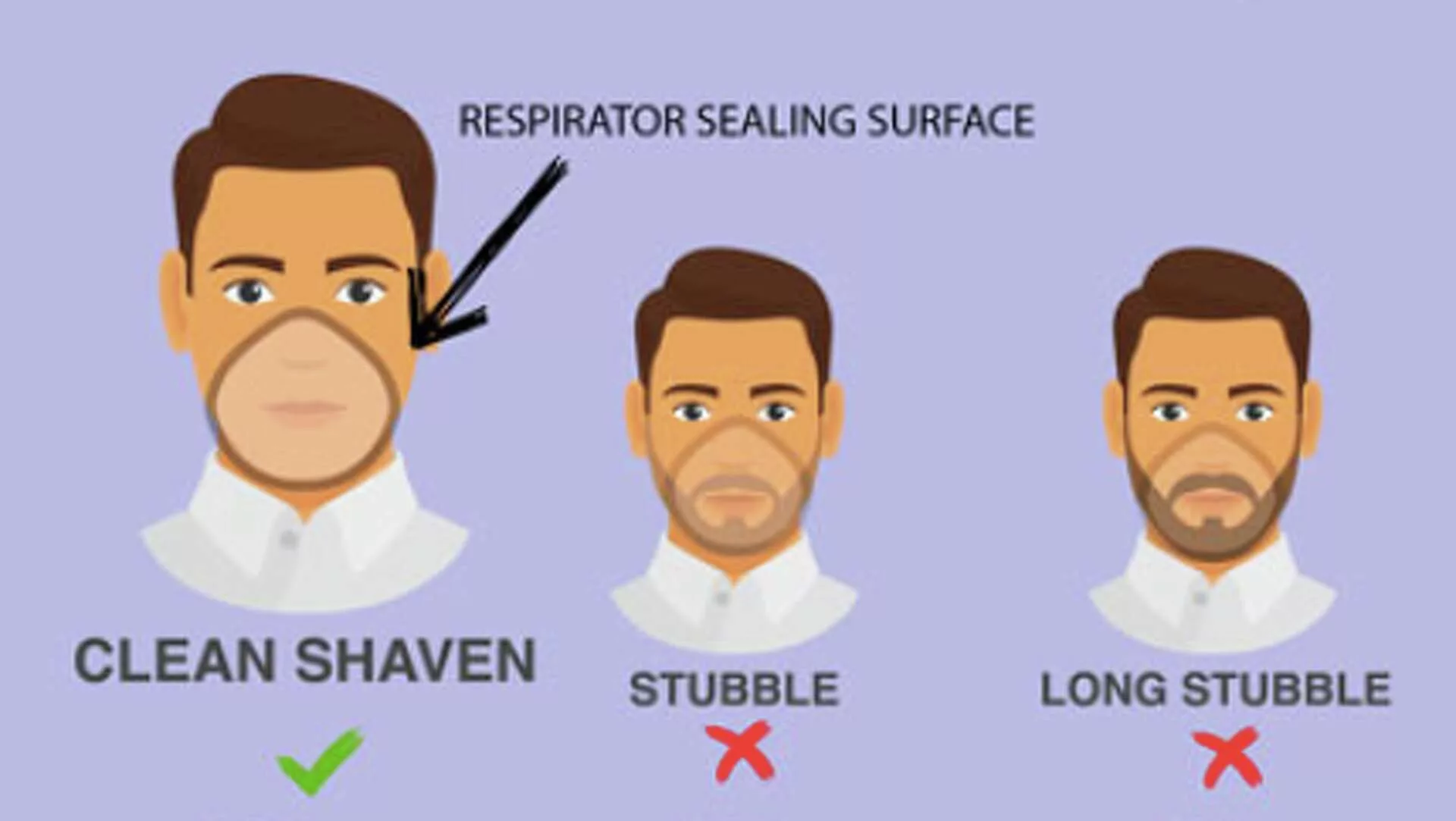

Face Piece Seal Protection

Employers must NOT allow workers to wear tight-fitting face pieces if they have:

- Facial hair that comes between the sealing surface.

- Facial hair that interferes with the respirator’s valve function.

- Any other condition that interferes with the seal or valve functions.

If an employee wears glasses, goggles or other PPE, you must ensure that it doesn’t interfere with the seal.

Workers who wear respirators are required to perform a user seal check before every use. This seal check should follow OR-OSHA’s procedures (Appendix B-1) or the recommended seal check by the manufacturer.

If respirator use is voluntary, the employer MAY provide filtering facepieces (particulate respirators) to employees who request them OR employees may use their own respirators voluntarily. Employers are NOT required to provide respirators, train, or fit test these voluntary users.

If you only allow the voluntary use of particulate respirators, you are responsible to provide the information in Appendix D or OAR 437-004-1041 to each user and ensure that the particulate respirators are kept in a sanitary condition.

If you allow employees to voluntarily use any other tight-fitting respirator, you have additional responsibilities:

- Provide Appendix D information to each voluntary user: “Information for Employees Using Respirators When Not Required Under the Standard”

- Ensure that the masks are kept in a sanitary condition.

- Provide an initial medical evaluation to ensure that the employee is able to use the respirator without adverse health effects.

- You must have a limited written respiratory program for voluntary users.

- The user must properly clean, store and maintain the respirator.

Employees can clean and maintain their own personal respirators or you can delegate the work to someone who has proper training and experience. Respirators must be checked for proper function and condition before each use and after they’re cleaned.

Cleaning and Disinfecting

- Ensure that respirators are cleaned and disinfected.

- Cleaning and disinfecting must be done using the procedures in Appendix B-2 of OR-OSHA’s respirator protection program or the manufacturer’s recommended procedures.

- Respirators used exclusively by one worker should be cleaned/disinfected as often as necessary to keep them sanitary.

- Respirators used by more than one worker should be cleaned and disinfected after each use, or before being worn by a different person.

- Clean/disinfect emergency respirators and fit test/training respirators after each use.

Storage

- Store all respirators to protect them from damage, contamination, dust, sunlight, extreme temperatures, excessive moisture, damaging chemicals, and so the facepieces and valves are not deformed. Large, self-sealing plastic bags are ideal for storing clean respirators.

- Never leave used filters, cartridges, or canisters on the respirator during storage. If reused, they should be stored separately from the respirator in their own sealed plastic bags and handled with the same precautions as the air contaminant they were used for.

- Keep emergency respirators accessible to the work area, in compartments or covers clearly marked for emergency respirators, and in accordance with manufacturer instructions.

Inspections

Employers must require respirator inspections as follows:

- Inspect all routine-use respirators before each use and during cleaning.

- Inspect emergency-use respirators at least monthly and document the inspection.

- Inspect escape respirators before taking them into the workplace for use.

Inspections should include:

- Check the respirator function.

- Tightness of connection.

- Condition of various parts (including face piece, head straps, valves, connecting tube, cartridges, canisters, or filters).

- Check of elastomeric parts (any parts that should return to its original shape after being deformed) for pliability and signs of deterioration.

For emergency-use respirators, employers must:

- Certify the respirator by documenting the date of inspection, name of the inspector, findings, required remedial action, and a serial number or other means of identifying the respirator

- Provide this information on a tag or label attached to the respirator storage compartment, or keep it with the respirator, or include it in paper or electronic inspection reports. Keep this information until the next report replaces it.

Repairs

- Do not use respirators that fail an inspection or are defective. Either discard them or repair them.

- Only people with appropriate training may repair or adjust respirators.

- Only the manufacturer’s NIOSH-approved parts designated for the particular make and model should be used.

- Repairs must conform to the manufacturer’s recommendations for the type of repair needed.

- Only the manufacturer or a technician trained by the manufacturer may repair or adjust the reducing and admission valves, regulators, and alarms.

** There is another set of standards for compressed air respirators. Please refer to the OR-OSHA respiratory protection standards for additional information.

Changing Filters, Cartridges, and Canisters

You must establish a schedule for changing filters, cartridges, and canisters based on the end-of-service life indicators or a maximum-use time determined by the manufacturer or product label, or first detection of breakthrough by the employee.

If respirators are required on the pesticide label, then the requirements for replacing filters, cartridges, and canisters in the Worker Protection Standard apply.

When particulate filtering respirators are used, the filters must be replaced:

- When breathing resistance becomes excessive.

- When the filter element has physical damage or tears.

- According to manufacturer’s recommendations or pesticide product labeling (whichever is more frequent).

- At the end of 8 hours of cumulative use if there are no other instructions or indications of service life.

When gas or vapor-removing respirators are used, the gas- or vapor-removing canisters or cartridges are to be replaced:

- At the first indication of odor, taste, or irritation.

- When breathing resistance becomes excessive.

- When required according to manufacturer’s recommendations or pesticide product labeling instructions, whichever is more frequent.

- If the employer has an OSHA respiratory protection program that specifies a maximum use time, then replace when that time is reached.

- At the end of 8 hours of cumulative use if there are no other instructions or indications of service life.

Printable Respiratory Protection Summary

A printable PDF summary of OR-OSHA’s respiratory protection rules.

OR-OSHA Division Rule Text: Respiratory Protection

Read OR-OSHA’s Division 4 rules about respiratory protection requirements.

Appendix A: Fit Testing Procedure

Download OR-OSHA Respiratory Protection Rule Appendix A: Fit Testing Procedure.

Appendix B-1: User Seal Check Procedures

Download OR-OSHA Respiratory Protection Rule Appendix B-1: User Seal Check Procedures.

Appendix B-2: Respirator Cleaning Procedures

Download OR-OSHA Respiratory Protection Rule Appendix B-2: Respirator Cleaning Procedures.

Appendix D: Information for Employees Voluntarily Using Respirators

Download OR-OSHA Respiratory Protection Rule Appendix D: Information for Employees Voluntarily Using Respirators (in English and Spanish).

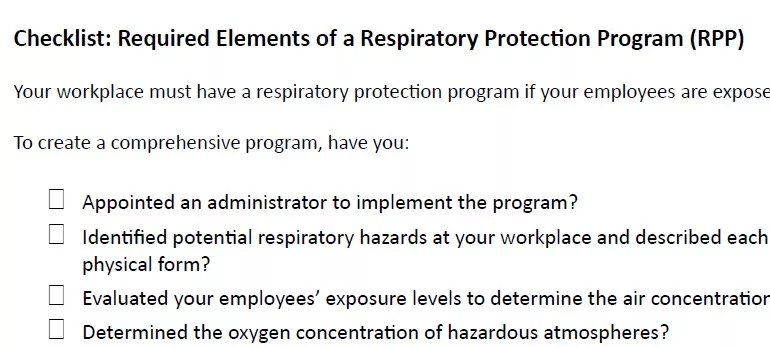

Checklist: Required Elements of a Respiratory Protection Program

Download the checklist of required elements of a respiratory protection program.

Written Template for Respiratory Protection Plan (Mandatory Use)

Download and customize this template to create your own written program for MANDATORY use of respirators.

Written Template for Respiratory Protection Plan (Voluntary Use)

Download and customize this template to create your own written program for VOLUNTARY use of respirators.

The Air You Breathe: OR-OSHA’s Respiratory Protection Guide for Ag Employers

Download a guide of respiratory protection requirements specifically for agricultural employers.

Ag Respiratory Protection Fact Sheet (English)

Read OR-OSHA’s Ag Respiratory Protection Fact Sheet in English.

Ag Respiratory Protection Fact Sheet (Spanish)

Read OR-OSHA’s Ag Respiratory Protection Fact Sheet in Spanish.

How to Perform a Fit Test

Read step-by-step instructions to properly perform a respirator fit test.

Additional Fit Testing Resources

Find additional information about respirator fit testing, including Frequently Asked Questions, fit testing supplies, etc.

Medical Evaluation Questionnaire (English)

Download the medical evaluation questionnaire for mandatory respirator use (English version).

Medical Evaluation Questionnaire (Spanish)

Download the medical evaluation questionnaire for mandatory respirator use (Spanish version).